Since the crack is on the top of the manifold, it is easily accessible.

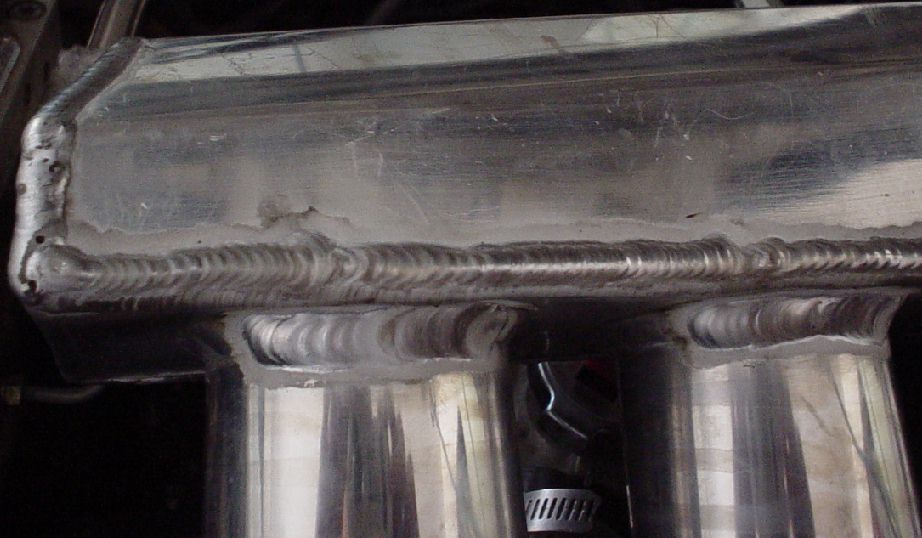

I was able to drive the car to a muffler shop with a TIG welder. A stronger and larger weld bead was placed on top of

the cracked area. The repair was immediately noticed, since boost response was recovered and WOT operation returned to reasonable

11.5 AFR's.

Racers all know that when you strengthen a certain area of a damaged

product, failure will occur next in the next weakest area. The Magnus held up for a few weeks, until the next drag strip track

night, of course.

First run of the night was an 11.1 pass.

2nd run 11.4

3rd run 12.1

4th run 13.8

The crack began in the middle of the 1st pass and became larger and larger until it could not hold

anymore boost. When I got home I hooked up the pressure tester and found that the leak this time was on the bottom of the

POS Magnus.

Since the crack is on the bottom of the manifold this time, the

Magnus must be removed completely from the car for repair. I instructed the welder to completely go over the entire manifold

with larger beads. I don't want another crack ever out of this POS.

Turns out that by welding the entire manifold, the heat from the repair process, ended up warping

the flange that mounts the manifold to the cylinder head. I needed to enlarge the holes in the flange just to get the manifold

to bolt on. I hooked up the pressure tester once again after the install was complete, and the manifold was holding boost

quite well. When I sprayed down the area with soapy water, I found tiny air bubbles leaking out of all 4 ports, right at the

warped cylinder head flange. It was not enough of a leak that I should be concerned about, but I could compensate that leak

with the tune.

|